R&D & Testing Facility

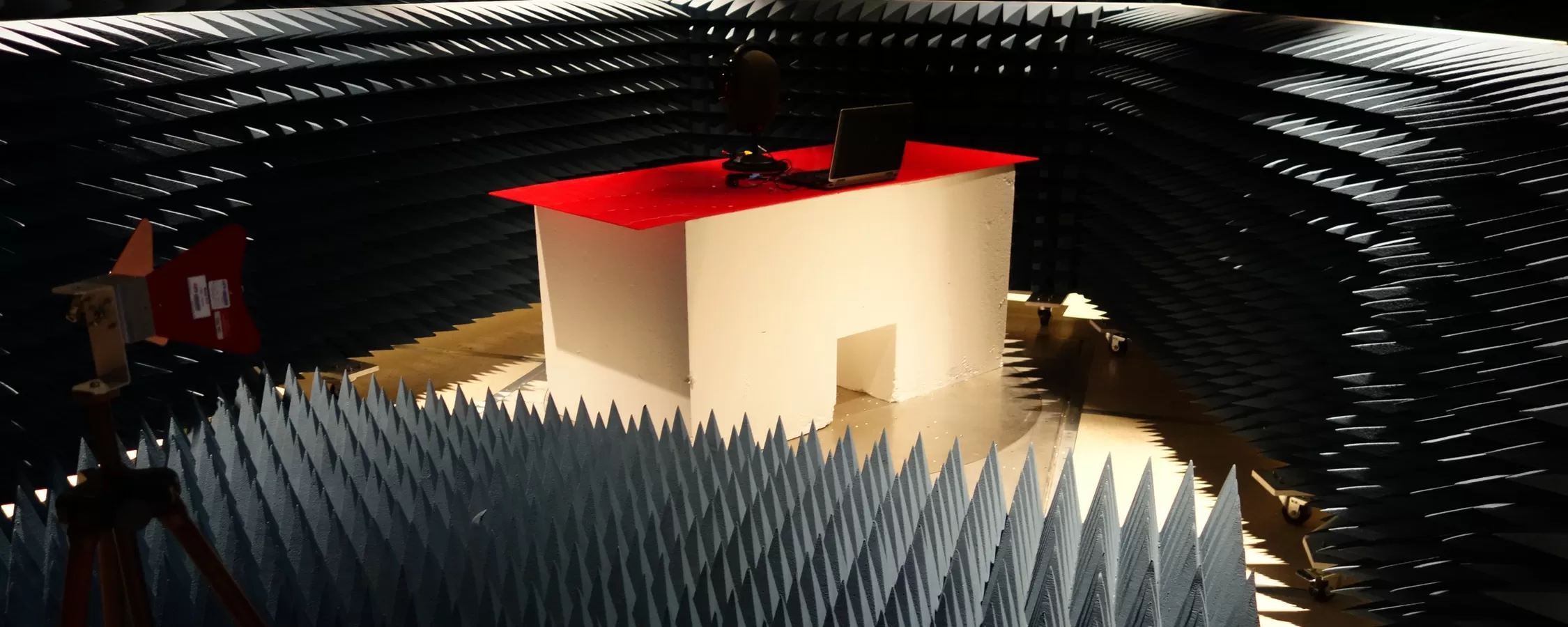

Logitech Inc. Headquarters – Anechoic Chamber Acoustic Engineering

Logitech Inc., a global leader in audio and peripherals, required a precision-engineered anechoic chamber at its headquarters in California, USA.

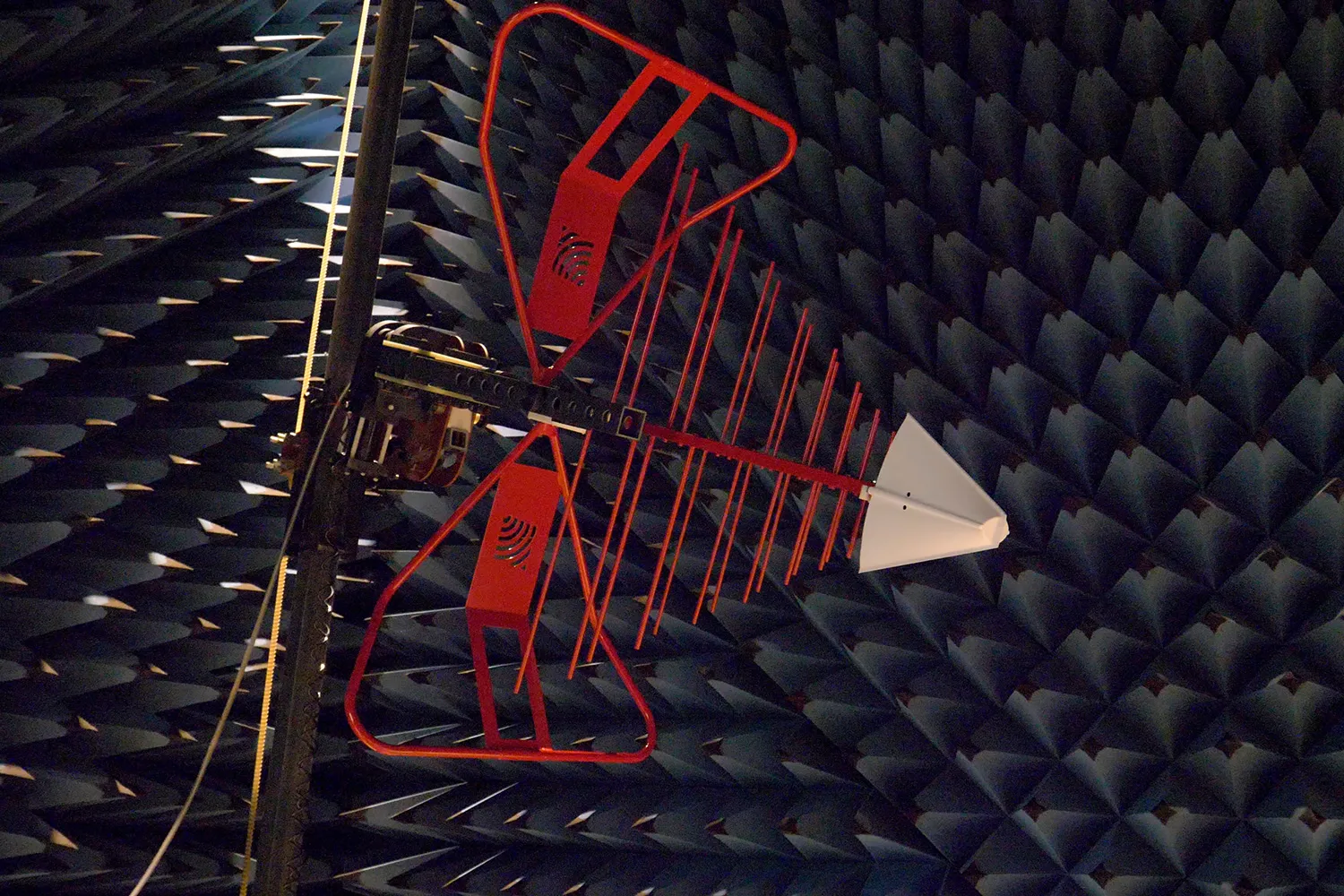

The facility is used for advanced R&D testing of headphones, microphones, speakers and communication devices where even minor reflections can affect results.

MMT Acoustix supplied high-performance, fire-rated anechoic foam wedges designed to create a fully sound-still, echo-free environment.

Across approximately 289 m² of chamber surface area, our wedges help Logitech engineers perform repeatable, high-accuracy acoustic measurements

that directly influence global product development.

Project Snapshot

Engineering Silence for a Global Audio Brand

Client

Logitech Inc. Headquarters

Location

California, USA

Application

Full-size anechoic chamber for audio R&D and product testing.

Coverage Area

Approx. 289 m² of walls and ceiling treated with wedges.

Key Acoustic Components

- Anechoic foam wedges – 200 × 200 × 750 mm profile.

- Density: 38 kg/m³ for balanced wide-band absorption.

- Fire rating: HF1, UL94 – suitable for international lab environments.

- Precision manufacturing for consistent wedge geometry across the chamber.

System Goal:

Deliver a fully controlled, echo-free acoustic field that meets international standards for product measurement, supporting Logitech’s internal testing protocols and certification needs.

Client Challenge

Creating a True Anechoic Environment for Critical Measurements

For Logitech, the anechoic chamber is a core asset in the development cycle of high-performance audio products. The acoustic demands go far beyond typical treatment:

- Zero-reflection requirement: The space needed to behave as a free field, with virtually no measurable echo.

- Wide-band absorption: High absorption from speech and music frequencies through to higher test bands.

- Strict fire performance: Materials had to meet HF1 / UL94 fire rating requirements for R&D facilities.

- Dimensional precision: Consistent wedge size and density to maintain accurate, predictable acoustic performance.

Our Approach

High-Density, Fire-Rated Anechoic Wedges for Absolute Control

Acoustic Design Input

- Interpreted Logitech’s internal acoustic criteria and chamber design parameters.

- Recommended wedge size and density to achieve the desired cutoff frequency and decay time.

- Ensured the foam formulation met international lab and building code expectations.

Engineered Wedge Geometry

- Manufactured wedges in 200 × 200 × 750 mm format for deep penetration and efficient absorption.

- Maintained 38 kg/m³ density to balance structural integrity with high absorption.

- Optimised geometry to minimise reflections and prevent standing wave build-up inside the chamber.

Fire & QC Certification

- Foam produced to meet HF1 / UL94 fire safety requirements.

- Batch-level checks for density, dimension and surface quality across all wedges.

- Coordinated packing and dispatch to support global shipment to California.

Products & Performance

Anechoic Wedges Tailored for World-Class Audio Testing

Anechoic Foam Wedges

Polyurethane foam wedges designed specifically for anechoic use, with deep profiles that provide strong attenuation over a wide frequency range.

Size & Density

Wedge size of 200 × 200 × 750 mm and a density of 38 kg/m³, carefully chosen to achieve the target anechoic performance in a full-scale chamber.

Fire-Rated Formulation

HF1 and UL94 compliance make the foam suitable for use in international R&D facilities where safety compliance is mandatory alongside acoustic performance.

Chamber Integration

Wedges were installed across the full wall and ceiling surfaces, creating a uniform acoustic field and enabling Logitech to conduct precise product measurements and calibration.

Results Delivered

A Silent Room for Global Audio Innovation

True Anechoic Behaviour

The completed chamber exhibits near-zero internal reflections, providing the quiet, neutral acoustic environment required for advanced audio testing and calibration.

Reliable Product Measurement

Logitech’s engineering teams can now perform repeatable, high-precision measurements on microphones, headphones and speakers that will be used by customers worldwide.

Safety & Compliance Achieved

HF1 / UL94 compliant materials ensure the chamber meets internal safety protocols and external certification expectations for an R&D environment.

Key Highlights

High-Precision Acoustics for a Global Technology Leader

- Engineered and supplied fire-rated anechoic wedges for a large-scale chamber at Logitech headquarters.

- Approx. 289 m² of wall and ceiling area treated for true anechoic behaviour.

- 38 kg/m³ density and HF1 / UL94 compliance for a balance of performance, safety and durability.

- Supported Logitech’s objective of creating a reference testing environment for future generations of audio products.

Need Anechoic Wedges?

From compact test booths to full-scale anechoic rooms, we can help design and supply the acoustic systems that meet your measurement standards, safety requirements and project timelines.